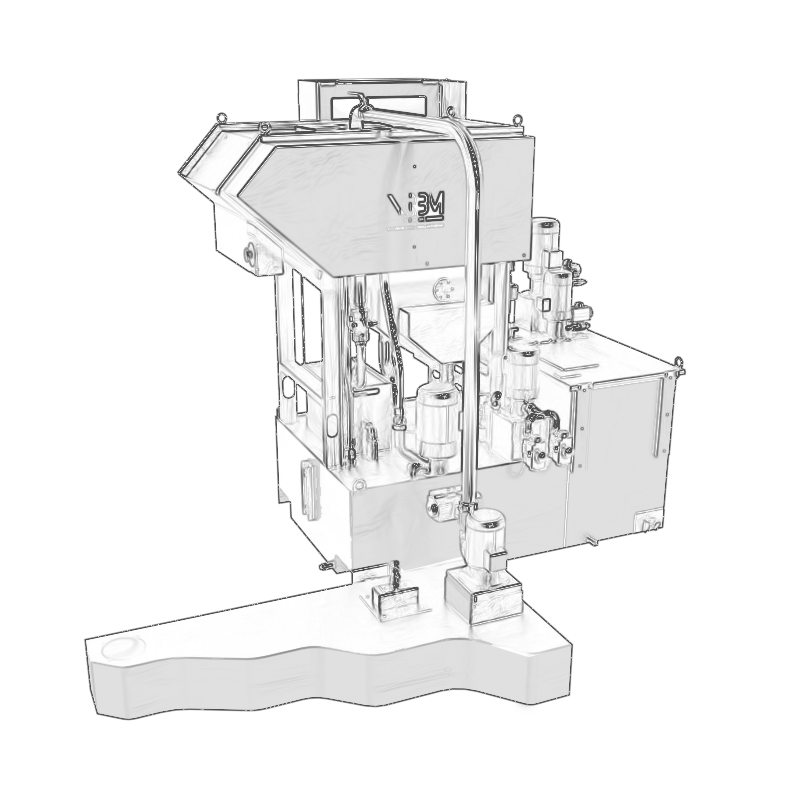

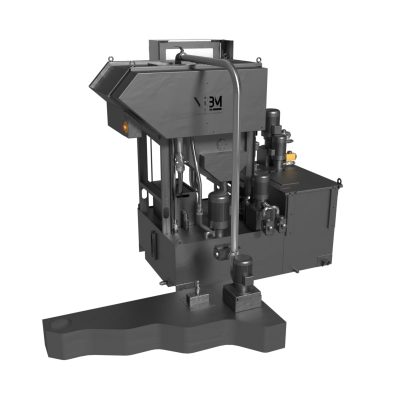

CO-RE

The CO-RE system is the integration between both technologies of rotofilter and IFDR. It perfectly matches both new machine tools and those equipped with standard solutions that, due to their construction or operation, do not meet the production requirements of the machine tool.

The main advantages of using CO-RE technology are:

1. Suction and prefiltration at 50 µm of all chips of a size of 4-5 mm dispersed in the cutting fluid.

2. Second filtration at 20 µm for using the coolant on the tools.

3. IFDR technology with integrated dynamic tramp oil separation that allows collecting tramp oil in a special tank.

4. Coolant’s oxygenation and cleaning from all pollutants.

5. Simple integration with any machine tool, new or used.

6. Chip management of any material without loss of efficiency.

7. Easy-to-manage integrated PLC with parameter adjustment, switchable in English.

8. Possibility to manage delivery pumps up to 70 bar.

9. Automatic coolant top up already integrated into the PLC.

10. Lower costs compared to the integrated system tank-rotofilter-IFDR.

11. Possible integration of the high energy efficiency chiller to control the coolant’s temperature, designed to work in production workshops.

CO-RE is at the top of the market for the quality of the components used, the cleaning, and the proper oxygenation of the cutting fluid and the absence of filter paper or other elements to be disposed of. It has a range of accessories that allows configuring the system according to the customer needs.

CO-RE systems comply with the machinery directive and are CE approved as stand-alone machines.