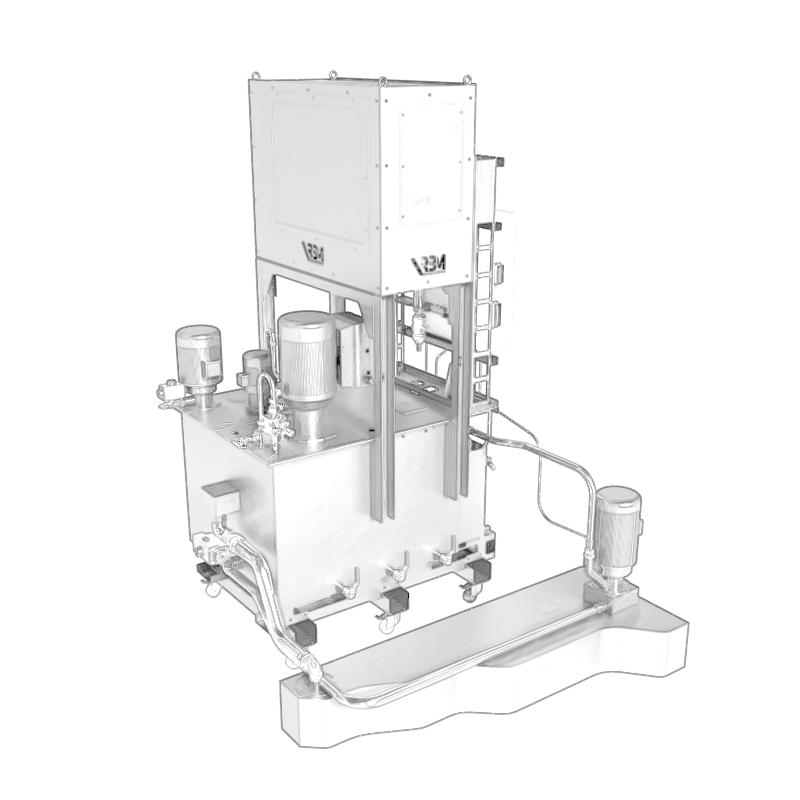

IFDR systems

The IFDR systems represent the apex of the technology proposed by RBM and are positioned at the highest market levels of the solutions offered for machine tools.

The main advantages of using IFDR technology are:

1. Separation and capture of all solid particles of a size larger than 10 µm with the standard systems and larger than 5 µm with the Precision systems.

2. Automatic extraction of separated particles, collected in special containers in relation to the chosen model and its configuration.

3. Dynamic tramp oil separation to extract automatically both oily and floating substances present in the coolant, ensuring the optimal oxygenation of the cutting fluid and the reduction of bacterial contamination.

4. Longer tool life thanks to the elimination of the abrasive component derived from hardened and highly harmful micrometric particles.

5. Simple maintenance with programmable and reduced dwell times.

6. Total absence of filtering elements to be disposed of as hazardous waste.

7. Sizing and control of high-pressure delivery pumps with an innovative concept of pressure/flow rate relationship.

8. Better control of chip breaking thanks to the use of high pressure and the thermal shock generated on the chip that is forming.

9. Automatic coolant top-up already integrated into the PLC.

10. Possible integration of the high energy efficiency chiller to control the coolant’s temperature, designed to work in production workshops.

IFDR systems comply with the machinery directive and are CE approved as stand-alone machines.

Thanks to the integration of the PLC on all systems and of specific software for managing the pressure/flow rate relationship, with particular attention to energy consumption, they can be included in integrated automation projects in compliance with Industry 4.0 directives.

Designed to be installed on all machine tools, the IFDRs are a modular project that allows expanding the volume of the systems, the flow rate of the filtered liquid and the possibility of mounting different delivery pumps, both in terms of hydraulic characteristics and quantity, giving rise to solutions customizable to customer needs.

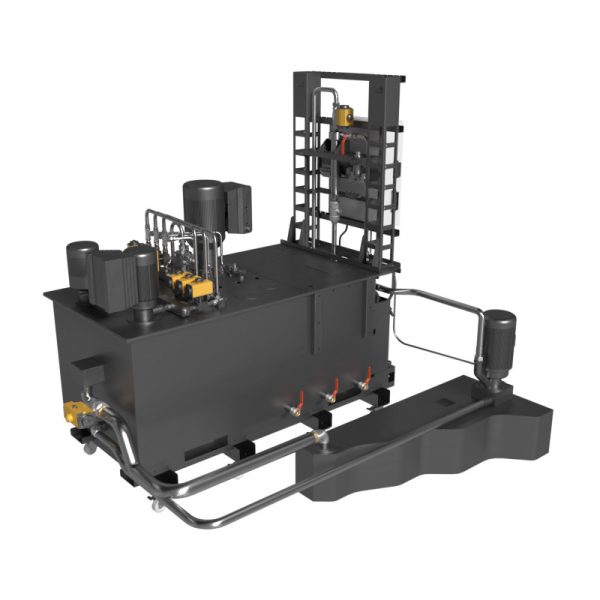

THE MODELS

IFDR systems offer a wide range of customizable models depending on the characteristics of the machine tools to which they will be combined, more precisely:

• Type of machine tool.

• Quantity and type of tools present on the machine tool.

• Integrated automation for machining on several shifts.

• Tank volumes and type of chip conveyors used.

To carry out the integration properly, three basic models are considered: 300 – 500 – 800, where this number represents the volume of liquid contained in the IFDR tank.