IFDR 800

IFDR 800

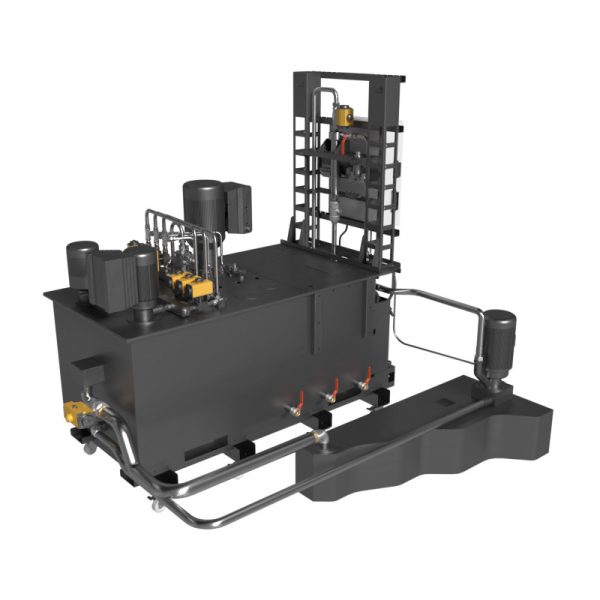

The model IFDR 800 includes in its basic configuration:

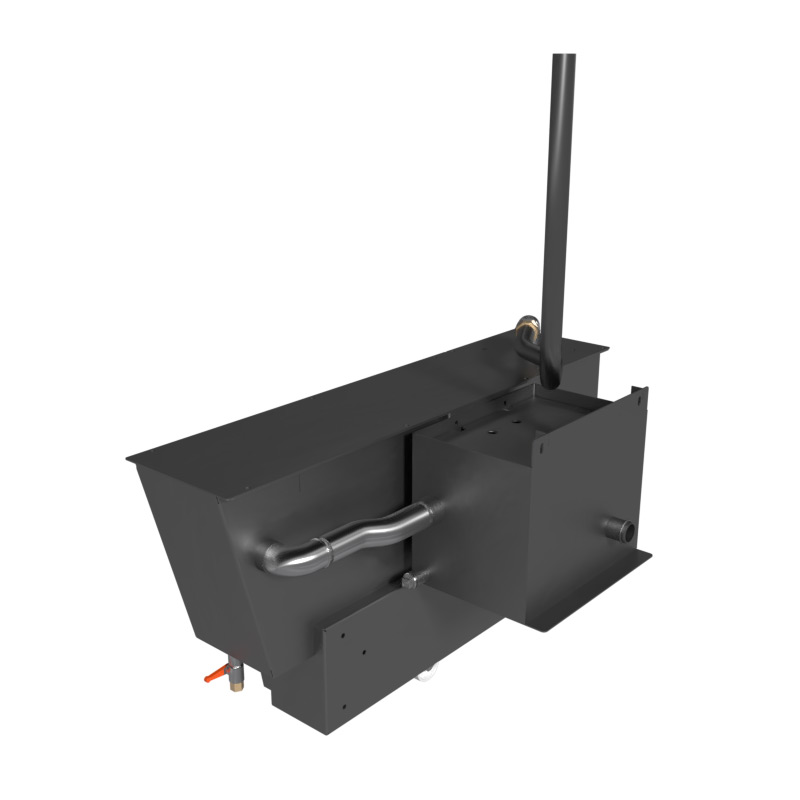

• Suction pump from the machine tool tank.

• Filtration unit below 10 µm with automatic sludge discharge.

• Electrical control panel with PLC management.

• Chiller prearrangement to control the coolant’s temperature.

There are two models, depending on the volume of filtered coolant that is delivered to the machine tool:

• IFDR 800/25 with a flow rate of 80 L/Min.

• IFDR 800/32 with a flow rate of 120 L/Min.

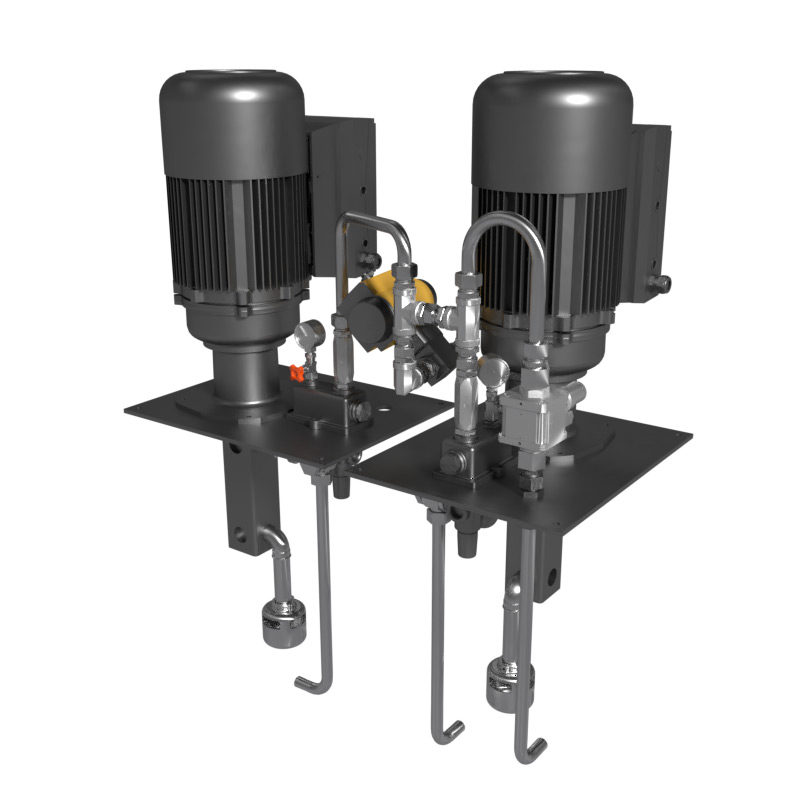

It can be configured with up to six delivery pumps, which can be customized according to the machine tool to which it is combined, also managed with inverters to optimize energy consumption, and with a wide range of accessories. Among these, the DUPLEX represents a system in the system able to recognize the tool that is used and, by optimizing energy consumption, manages the pressure/flow rate relationship up to a maximum of 120 L/Min at 70 bar.